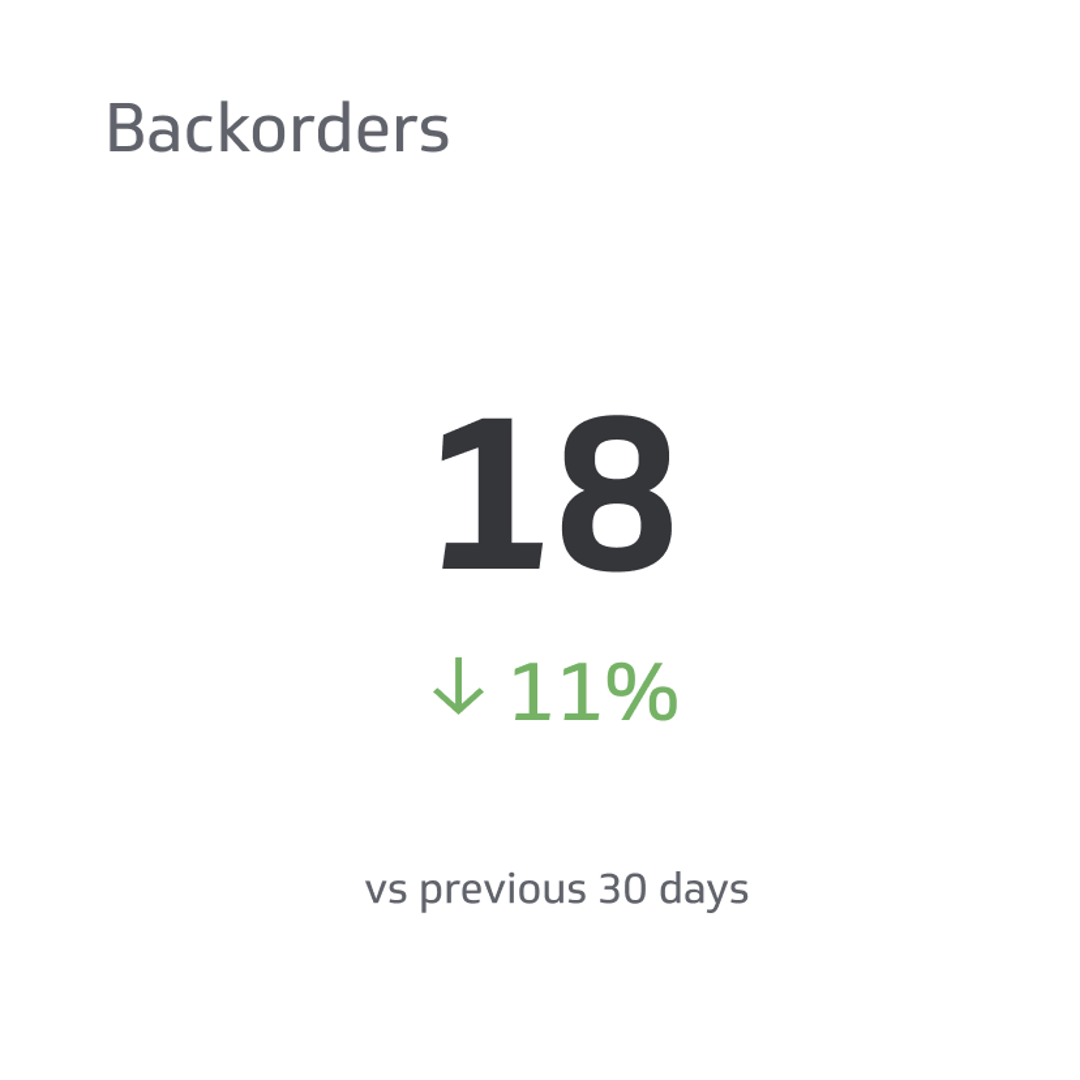

Backorder

A backorder refers to an order for specific products or services that can't be fulfilled due to the lack of supply.

Track all your Supply Chain KPIs in one place

Sign up for free and start making decisions for your business with confidence.

Backorders are a huge inconvenience, especially when there's a massive demand for a specific product. But this doesn't mean your customers can't place orders and wait for the products to be restocked. Usually, this is what most e-commerce stores do. Once they run out of stock, they allow customers to place orders, and they should expect the goods to be delivered within a certain time.

To run your e-commerce store successfully, it's essential to know how to manage inventory effectively and work towards reducing backorders. After all, improving your overall customer experience is crucial, which makes it important to ensure they get what they want on time.

We'll walk you through everything you need to know about reducing backorders or using them to your advantage.

What Does a Backorder Mean?

A backorder refers to an order for specific products or services that can't be fulfilled due to the lack of supply. Backorders normally happen when a business can't meet a massive demand for products/services but opt to allow customers to make their orders. Of course, there are pros and cons of backordering.

Backordering is normal, and if you're experiencing it, it doesn't mean you'll lose your clients. However, if not well-managed, your customers might lose trust in you. You're more likely to lose your customers if you keep disappointing them, giving them excuses to wait while you restock.

For most businesses that rely on the just-in-time inventory management strategy, where they stock goods in demand, backordering helps to sustain their businesses. In this case, backordering helps to lower the holding costs of inventory.

How Backorders Work

With the right inventory management, a business will always have enough goods to meet its demand. Whether you're offering services or selling products, inventory management helps determine what your customers need and whether you can deliver. There are times when the customer demand exceeds what you can supply. When this happens, your customers can place their orders as you restock.

The orders your customers place, even when you don't have the stock, are identified as backorders. These orders are considered backorders since the items aren't in stock at the time of order, but your customers will eventually receive the products. The advantage here is that your customers will have to wait until you restock and ship the goods to them. This is one of the main advantages of backorders.

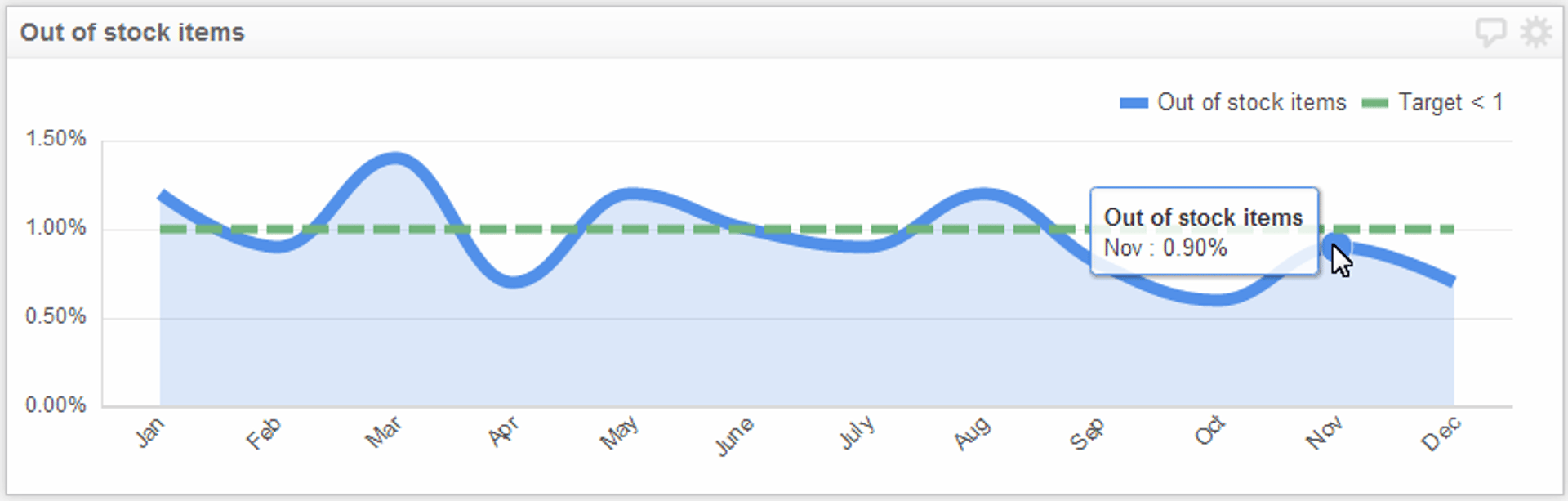

Difference between Backorder and Out of Stock

Backordering differs from out-of-stock. When you're out of stock, you don't have the products your customers want, and you're not sure when you'll restock. On the other hand, backordering works differently since you know when you're likely to restock products in your store.

Generally, with backordering, there's some hope that your customers will get what they want in the foreseeable future. Sometimes it might take a while, but at the end of the day, your customers will be glad they received their products from your brand. Most customers will be willing to wait if you're a reputable brand, since they trust you can deliver.

Importance of Backordering

Backordering is a great way to ensure you don't lose your customers to your rivals. Your customers trust that you'll deliver your products/services on time. When the demand exceeds what you can supply within a specific time, backordering usually comes in handy.

Here are the benefits of backordering:

Reduced Costs

Backordering helps your business to reduce warehousing expenses. You don't have to overstock products because they are in high demand. This is a huge advantage for new businesses as they can cut warehousing costs. What's more, small businesses can use this to their advantage and stock only a few items customers want.

Another benefit is that backordering frees up capital that would have been used on stocking and paying for holding costs. Producing on demand works best for new businesses or when introducing a new product.

Product Customization

Backordering also allows for product customization, as it involves working with the supplier to deliver goods to your customers. In this regard, it's easy to accommodate your customers' requests. Most customers will fancy this unique selling point and prefer to rely on your brand over your competitors.

Enhanced Product and Brand Value

Tech companies are gradually using backordering as a marketing strategy to lure customers into buying devices even before being released to the market. You may have noticed some smartphone companies allowing customers to make their orders before launching the products.

While this is how backordering works, these tech firms create curiosity around their products. As a result, backordering can help to increase product and brand value in the long run.

Backordering to Test the Market

Using the example mentioned above, backordering can be a great way to test the market. Backordered products can help a business to gauge the market's interest in new products. It's less risky to backorder products since you produce and deliver on demand.

Your customers' response to the backordered products will determine whether you need to stock them or settle for alternative items. Essentially, your market knowledge will help to create awareness and allow you to meet your customers' demands ahead of your competitors.

Reduced Waste

Stocking only a few products your customers want helps to prevent or reduce potential waste. Backordering guarantees you don't hang around with unsold items on your shelves. It works best when you're selling seasonal products or services.

Higher Discounts for Customers

Backordering allows you to save on holding costs and other expenses involved in sitting around with dead stock. The more you save, the more likely you can offer your customers higher discounts. It's a win-win for you and your customers.

Increase Sales

Backordering items can also lead to increased sales. Usually, backordered products are costlier than products in stock when customers are buying them. Customers consider these products rare, which leads to an unexpected spike in demand.

There are also instances where backordered items have a short lead time than those bought from manufacturers or suppliers since they can be shipped locally. In these scenarios, backordering helps to increase the sales of such products.

It's also worth noting that backordering here helps to meet customer satisfaction as they don't have to wait until you restock the products.

Better Forecasting

Backordering supports better forecasting as it helps businesses track inventory effectively and anticipate future demand. With time, a company can easily understand how customers respond to new products or services. This also leads to better customer satisfaction.

Disadvantages of Backorders

While backorders come with certain benefits, there are instances when they are detrimental to your business. This is probably why most companies will do their best to avoid backorders.

Here are some reasons you should try to reduce or manage backorders.

Loss of Customers

Customers might be patient with you the first time you experience a backorder. However, if this keeps happening, you risk losing your customers. Your clients will grow frustrated if they keep visiting your e-commerce store only to find the products they need are out of stock. Not all customers will be patient for you to restock the items.

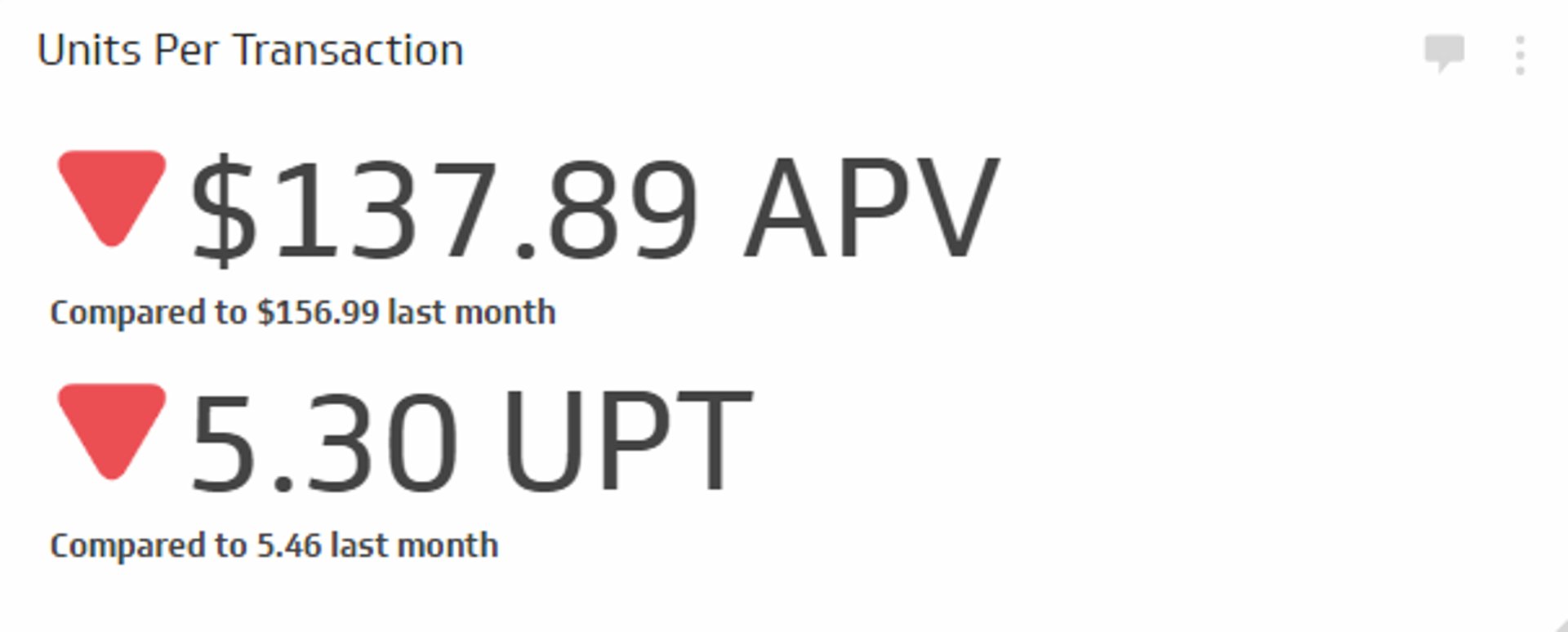

Declining Sales

If you're losing customers, you should also expect to see a drop in sales. We mentioned previously that backordering could help to lure customers into buying products that seem limited in the market. But this is a considerable risk if your backordered items delay. Some clients might not be willing to wait more than two days to receive their products. You risk losing sales and customers at the same time.

Increased Use of Resources

Backordering will also put your business in a situation where they have to spend more resources to fix the issue. Your customer service team will spend countless hours communicating with customers about the pending orders and how long they should wait. Responding to customer requests and complaints takes a lot of time and energy, and this will likely affect your productivity.

What Causes Backorders

Here's a look at some common causes of backorders in most businesses.

Demand Fluctuation

The main reason why businesses experience backorders is due to demand fluctuation. When the demand for certain products is unpredictable, it's daunting to gauge the number of items your customers require. For instance, if there's a surge in demand because of a holiday, this might affect your ability to meet the growing demand. A sudden increase in the popularity of your product, because it's trending on social media can also lead to backorders.

Supply Disruptions

Supply disruptions can also cause delays, leading to backorders. If products have to be shipped overseas, there are instances where suppliers might delay to dispatch products. Shipping delays might occur because of unavoidable acts of nature, regulatory issues, dock strikes, and more. Since you don't want to lose customers, lagging lead times will push you to backorder the products.

Low Safety Stock

Proper inventory management will help prevent your business from overstocking or understocking products. A safety stock acts like a safety net to continue supplying products during emergencies. For instance, in case of supply chain failure, your safety stock ensures you meet your customers' needs. The number of products to keep as your safety stock depends on the demand. If the items are in season, consider keeping a huge safety stock to avoid stockouts.

Inaccurate Forecasting

The best planning efforts will help ensure you don't run out of stock. But without proper inventory management, you risk operating under low safety stock, which could easily lead to backorders.

Human Errors

Human errors can also cause backorders. Usually, this happens when your staff marks items as backorders without knowing they are available. Errors from retailers can also lead to backorders. A backorder can occur if a retailer accepts an order in the supply chain when it's out of stock.

Tips to Minimize Backorders

Most businesses dread backorders, but the reality is that they are sometimes unavoidable. The best thing you can do is to learn to manage them and ensure they don't occur frequently.

Increase Your Safety Stock

Working with a sound inventory management system will help you to keep track of your stock at all times. Your employees will be more aware of stocked items and what needs restocking.

Once you understand the market demand, consider increasing your safety stock. Set a safety stock that can comfortably handle frequent unexpected demands. If you've been in business for some time, you know how your customers respond to your products. This means it shouldn't be difficult to know the correct safety stock to keep.

Regularly Keep an Eye on Stock Levels

Items in high demand will run out of stock faster than you can replenish them. Regularly monitor the stock levels of such items to ensure you don't end up disappointing your customers. Keep close tabs on popular products since there are instances when your employees might fail to make purchase order decisions on time.

Diversify Suppliers

There's nothing wrong with having one supplier, but it's a considerable risk since things can fail to go as planned. It's much safer to have multiple reliable suppliers you can turn to in emergencies.

Communicate with Customers Proactively

If there are issues that could lead to backorders, be sure to inform your clients in advance. Don't wait until your customers question when they will receive their items. Doing this will provide customers with the reassurance they need that they will get the products on time. For an e-commerce store, place alerts on products and the estimated time customers should wait. By doing this, customers will buy the products knowing there are potential delays.

It's also crucial that you manage your customers' expectations by letting them know why there are product delays. Maybe you're dealing with an unexpected demand or a manufacturer supply issue. Be sure to talk to your customers about this. You could also notify your customers that the backordered products are available.

Increase Your Stock Capacity

Sudden changes in demand will occur from time to time, especially if you're offering seasonal products. To counter such sudden changes, consider increasing your stock capacity before the season begins.

You've studied your customers for some time, and you know they will visit your store to get the products. So, stock in advance. This might mean working with a third-party logistics company to offer more storage space.

The needs of your customers should be prioritized above anything else. You don't want to lose them to your competitors because you didn't foresee the rising demand. Remember to stock with caution since excess inventory can lead to huge losses.

Managing Fulfillment of Backorders

Backodering has its pros and cons, but it's important that you learn how to manage them effectively and ensure they're not there in the first place. Inventory management will help you to foresee unexpected demands. However, it's also crucial to implement best practices as they ensure you know how to fulfill the backorders without losing your customers.

Here are best practices to meet customer demands for backordered products.

Communication is Key

With excellent communication, you can be sure there will be no need for backorders. Communicating up and down the supply chain ensures you know how to deal with emergencies.

In this case, supplies will update you if there are any concerns that need to be addressed. If inventory shortages happen, your good communication with the manufacturer, supplier, and retailers will prevent you from accepting order requests you can't meet. In turn, this also guarantees you don't disappoint your customers.

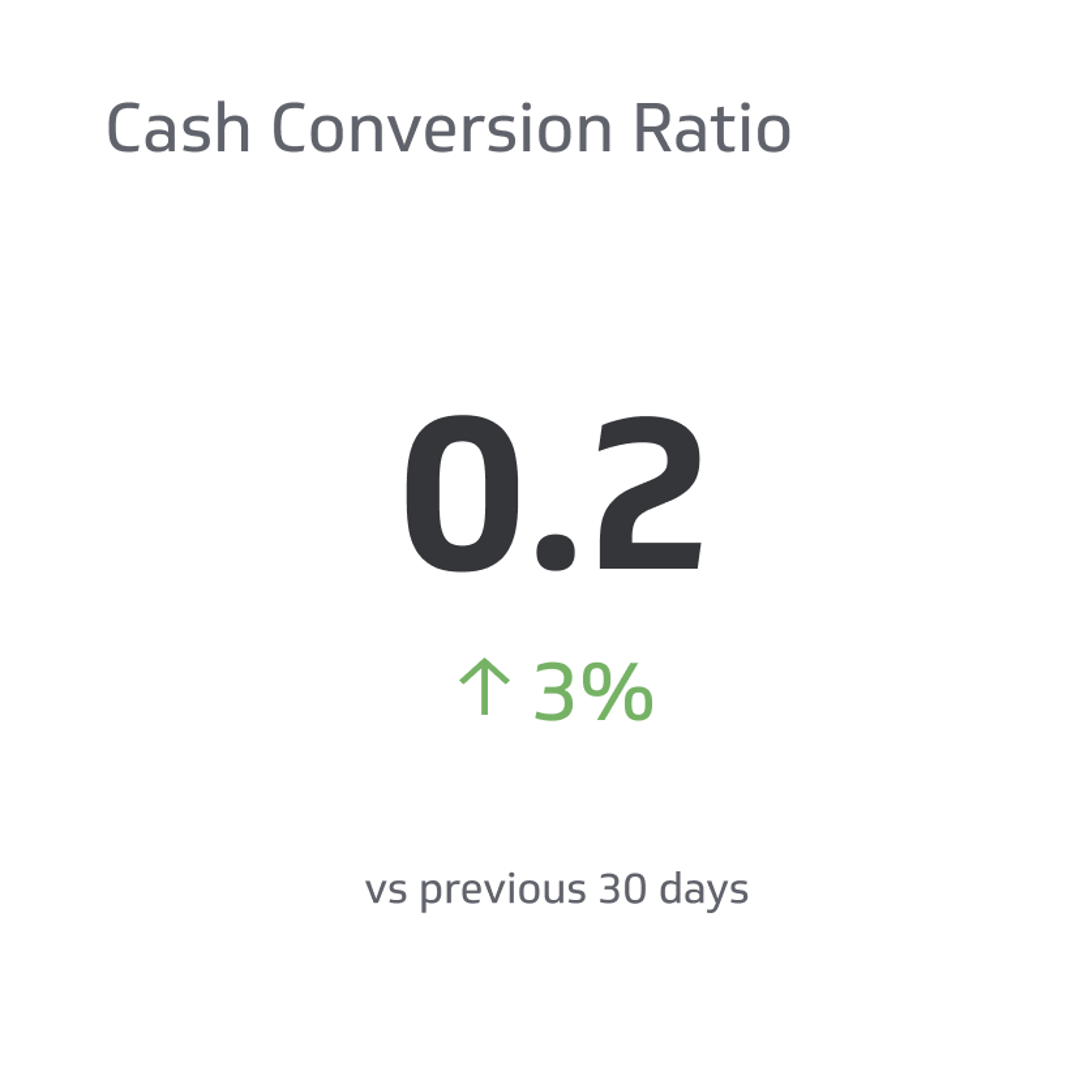

Use Data-Driven Inventory Management

Data-driven inventory management is another effective strategy that will prevent your business from experiencing stock outages. With data-driven inventory management solutions, real-time inventory visibility will reduce or prevent the need for backorders.

Warehouse Management

Hiring the right people to help you manage your warehouse can also make a huge difference in managing backorders. Experienced employees in warehouse management will work toward improving inventory accuracy, which reduces backorders. The right individuals will also expedite backorder fulfillment.

Use Accurate Forecasts

Accurate forecasts about the backordered items' arrival can help build trust with your customers. You should note that accurate predictions also give your customers a rough estimate about when they are likely to receive their products. Providing them with this information allows them to decide whether to proceed with the backorders or wait for the items to arrive. Ultimately, this prevents cancelations.

The key issue here is that you should have all the necessary information your clients want to hear from you. Don't give your customers a reason to think that you don't consider their demands.

Offer Incentives

Backordered items mean your customers must wait longer to receive their goods. If your competitors offer similar things for the same price, your customers might buy from them.

To lure your customers to buy from you and wait for the products to be delivered, you should consider offering incentives. You want to make your customers feel it's worth buying from you. While they have to wait for 7-10 days, offering incentives is one effective way to convince them.

People are always looking for convenience when shopping online. If you can't meet their demand, you will likely lose them to your competitors. Customers can quickly navigate to a different e-commerce store with just a few clicks. Therefore, when dealing with backordered products, your customers' tastes and preferences should be prioritized.

You don't have to lose customers due to backorders. Communicate about the backorders and entice your customers with freebies and discounts. More importantly, use data-driven inventory management to ensure you don't miss out on any possible stock outages.

Backorder FAQs

Here’s everything you need to know about backorders.

How long do backorders take?

Backorders can take longer or shorter depending on several factors, including stock availability, shipping duration, and so on. It's essential to communicate with your customers about the delays proactively.

How should you handle a backorder?

The best way to handle backorders is to try and avoid them in the first place. This means implementing inventory management best practices in your business.

How do you communicate about backorders to your customers?

Communicating about potential product delays is very important. With proper inventory management practices, you should accurately predict when you'll restock your products. You can text or email your clients informing them of the product's availability.

What happens during backordering?

Backordering allows customers to buy your products even when they are out of stock. Once your customers buy the goods from you, they expect to receive them within a specific timeframe. It's important to let your customers know when they should expect to receive their items.

Final Thoughts

Allowing customers to backorder items means that you might increase your sales to customers. As long as you have a good and reliable system to track inventory and communicate with customers, this is a great way to keep customers happy and increase your bottom line.

Related Metrics & KPIs