Inventory Dashboard

An inventory dashboard offers a clear and immediate view of stock levels and supply chain metrics, making it easier to manage inventory efficiently.

What is an Inventory Dashboard?

Inventory dashboards provide real-time stock levels and organize data to streamline inventory management, ensuring that products are always available. They support smart purchasing decisions by analyzing trends in stock movement.

By keeping products available, these dashboards prevent missed sales and allow you to adjust quickly to market changes, thereby improving customer satisfaction. They also support strategic supplier planning and risk reduction.

Inventory dashboards are crucial for staying competitive and boosting sales with efficient inventory management.

Examples of Inventory Dashboards

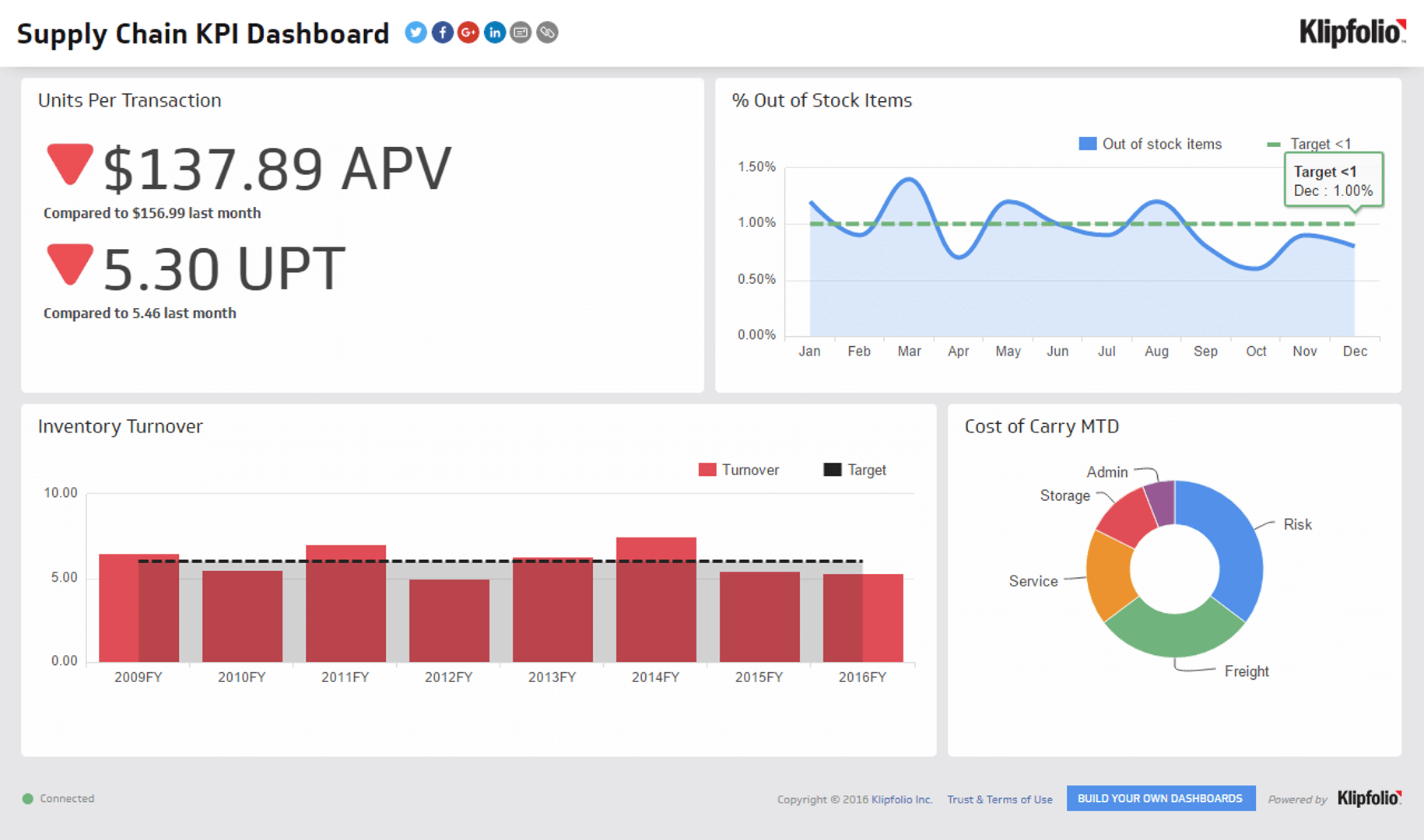

Stock Management Dashboard

A stock management dashboard displays inventory metrics, enabling businesses to manage their inventory more efficiently. It tracks and analyzes data regarding stock levels, sales patterns, and replenishment cycles, offering insights into inventory management.

Who’s it for | Retail operations coordinators, e-commerce inventory strategists, warehouse data analysts, supply chain consultants, procurement specialists |

How often it's needed | Daily, weekly, bi-weekly, monthly, quarterly |

Covered KPIs | Exact item count per SKU, inventory turnover, percentage of out-of-stock items, surplus inventory percentages, velocity of product sales per channel, inventory-to-sales ratios, average shelf time before dispatch, precise reorder triggers, calculated economic order quantity (EOQ), forecasted demand versus actual demand correlation |

Retail Inventory Dashboard

Retail inventory dashboards make it easier for retail teams to manage stock. They collect and analyze data on product quantities and buying trends, helping stores restock effectively. This prevents stock shortages and opens up more sales opportunities.

Who’s it for | Store managers, retail analysts, merchandise planners, inventory control managers, e-commerce operations teams |

How often it's needed | Daily, weekly, bi-weekly, monthly, quarterly |

Covered KPIs | Detailed item quantities by SKU, inventory turnover ratios specific to retail, incidents and impact of out-of-stock events, excess stock percentages by category, sales velocity of products by location, optimized stock-to-sales ratios per product line, average duration before in-store replenishment, targeted reorder points for each product, ideal economic order quantity for retail operations, alignment of forecasted sales with actual sales data |

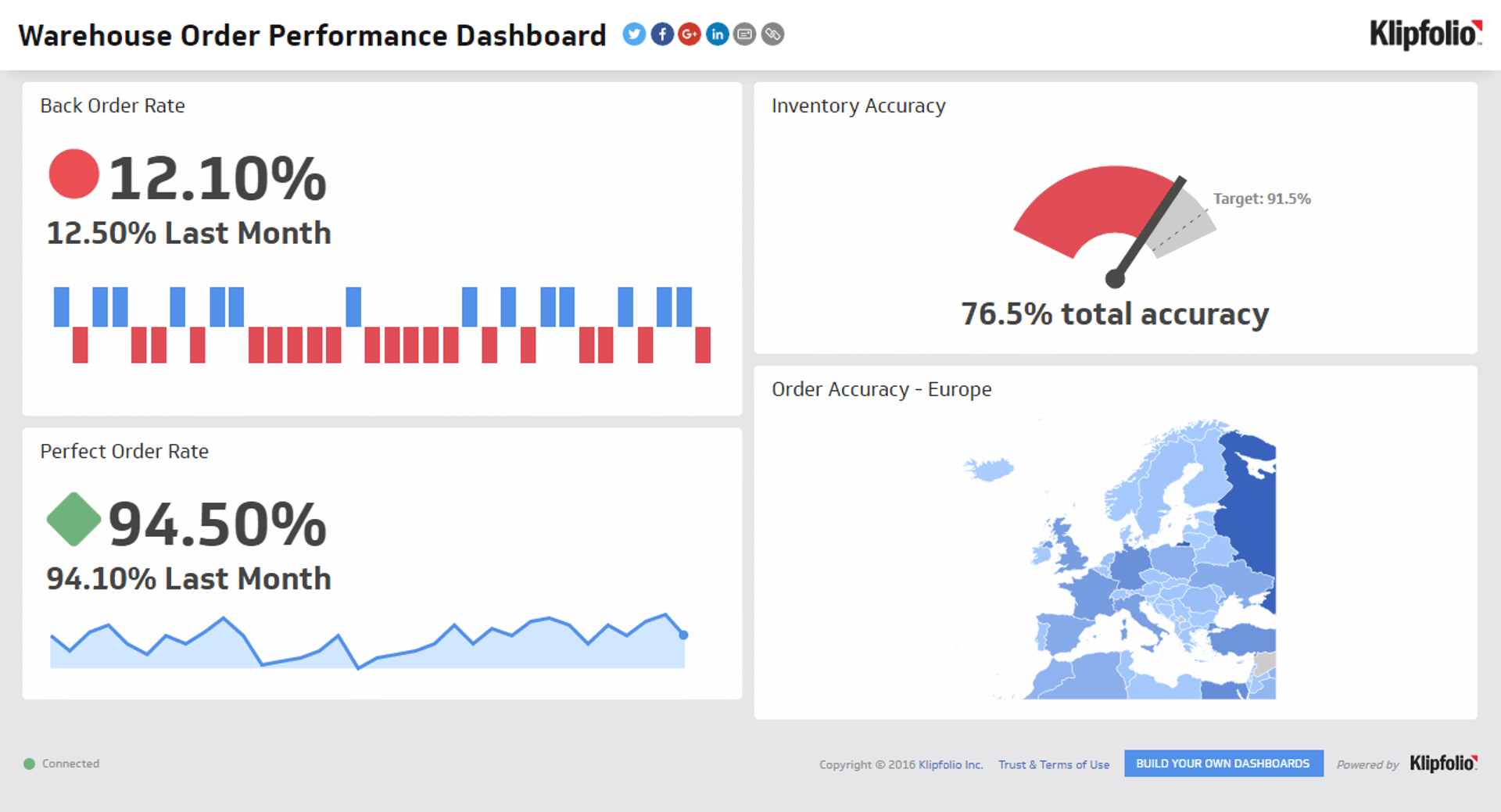

Warehouse Efficiency Dashboard

Warehouse efficiency dashboards improve warehouse operations by highlighting bottlenecks and inefficiencies. They help you optimize order processing, storage management, and staff allocation procedures.

Who’s it for | Warehouse managers, inventory control specialists, operations supervisors, distribution coordinators, logistics analysts |

How often it's needed | Daily, weekly, bi-weekly, monthly, quarterly |

Covered KPIs | Storage space utilization rate, order picking accuracy, average time from order receipt to dispatch, workforce productivity levels, incidents of picking and shipping errors, rate of returns due to faulty processing, equipment and resource efficiency rates, time spent on receiving and stocking inventory, total cost of warehouse operations, inventory accuracy |

Manufacturing Inventory Dashboard

A manufacturing inventory dashboard clearly shows reorder levels and downtime or delays due to materials shortages. It tracks and analyzes data on raw material levels, production rates, and work-in-progress items, offering insights for optimizing inventory management and improving efficiency.

Who’s it for | Plant managers, production planning and control officers, inventory control specialists, operations analysts, supply chain and logistics managers |

How often it's needed | Daily, weekly, bi-weekly, monthly, quarterly |

Covered KPIs | Current inventory levels of raw materials, count of items in process and finished goods inventory, production cycle times and efficiency rates, inventory turnover rate for raw materials and finished goods, rate of scrap or waste materials, downtime or delays due to materials shortage, reorder levels for raw materials, lead times for raw material delivery and production, forecasted vs. actual usage rates of materials, EOQ for optimal inventory levels |

Sales Dashboard

A sales dashboard provides a clear view of sales data and its effect on your inventory. It helps analyze how sales trends and patterns influence stock levels, allowing you to spot potential shortages or surpluses before they become issues.

Who’s it for | Sales managers, marketing professionals tracking campaign performance, business development teams, financial analysts, customer relationship managers |

How often it's needed | Daily, weekly, bi-weekly, monthly, quarterly |

Covered KPIs | Total revenue, revenue per SKU, sales conversion rate, lead conversion rate, customer acquisition cost (CAC), customer lifetime value (CLV), sales growth rates, product performance, category sales trends, average order value (AOV), purchase frequency, sales pipeline efficiency, closing ratios, market penetration, share statistics, year-over-year and quarter-over-quarter sales comparisons, customer satisfaction (CSAT) rates, retention rates |

Inventory Valuation Dashboard

The inventory valuation dashboard displays your current stock's worth. It offers insights into inventory financial value, helping finance and inventory teams identify strengths and weaknesses. This data guides decisions on stock levels, purchasing, and strategy, optimizing inventory management.

Who’s it for | Inventory managers, finance managers, supply chain managers, business owners |

How often it's needed | Daily, weekly, monthly |

Covered KPIs | Current inventory value, inventory turnover ratio, days of supply, carrying costs, obsolete stock value, inventory accuracy, write-offs and adjustments, valuation method comparisons (FIFO, LIFO, Average Cost) |

Accounting Inventory Dashboard

An accounting inventory dashboard helps keep your financial records in sync with your physical stock, making it easier for teams to spot and fix discrepancies. By clearly showing where your records and actual inventory match—or don't—it highlights areas that need attention, reducing errors and improving overall accuracy.

Who’s it for | Financial controllers, accounting managers, cost accountants, chief financial officers (CFOs), business analysts |

How often it's needed | Daily, weekly, bi-weekly, monthly, quarterly, yearly |

Covered KPIs | Total value of inventory on hand, cost of goods sold (COGS), aging inventory costs, gross margin return on inventory (GMROI), inventory carrying costs, write-offs and adjustments value, inventory turnover ratio, average days to sell inventory, return on inventory investment (ROII), cost per item per SKU |

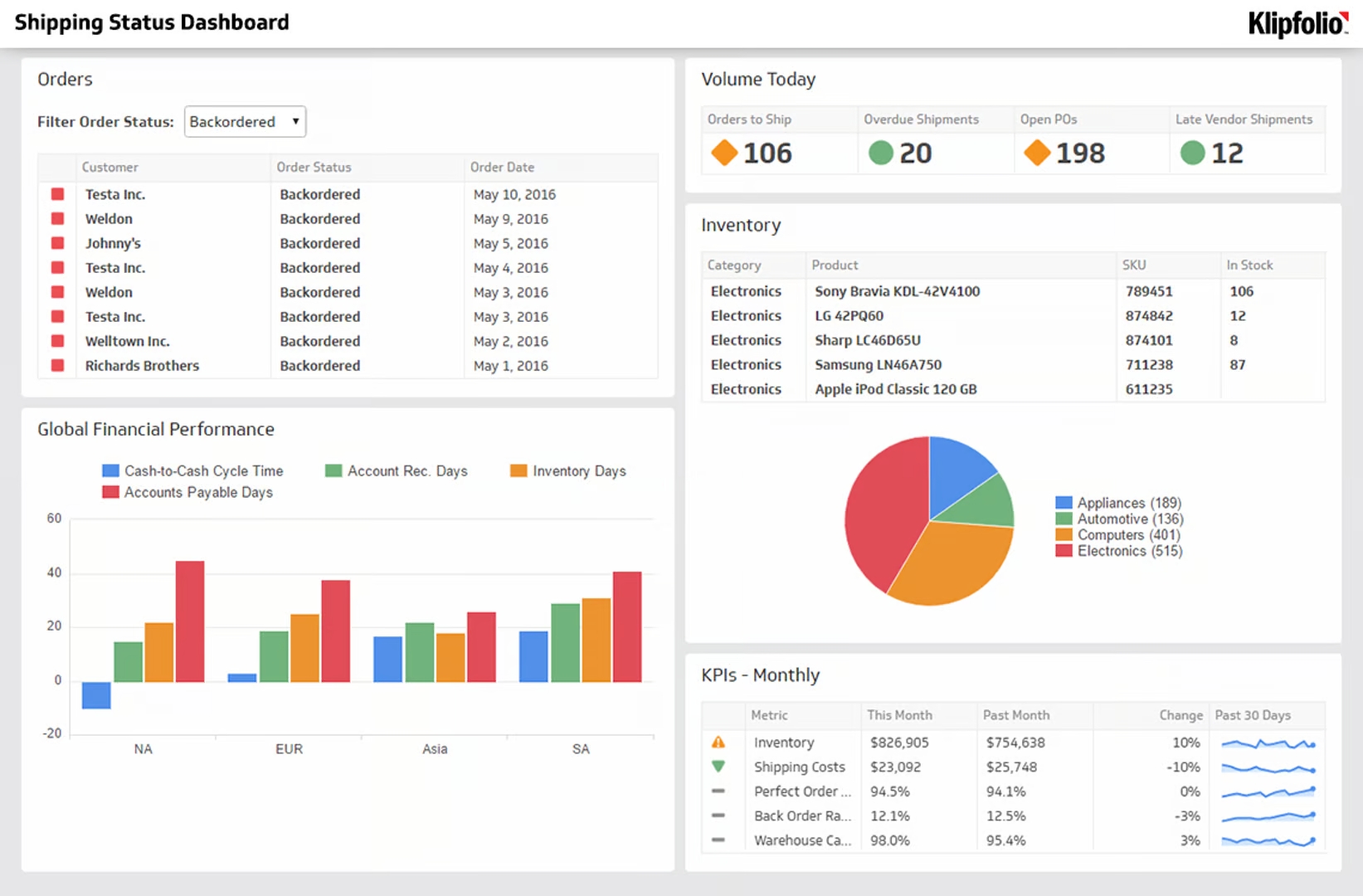

Shipment Status Dashboard

A shipment status dashboard keeps you updated on live and historical shipment information. It helps businesses track goods at every stage of the shipping process. The dashboard also provides insights into transit times, evaluates the performance of different delivery methods, and assesses the effectiveness of carriers.

Who’s it for | Logistics coordinators, shipping managers, operations directors, customer service teams, supply chain analysts |

How often it's needed | Real-time, hourly, daily, weekly |

Covered KPIs | Number of shipments in transit, on-time delivery rate, average transit time, carrier performance scores, percentage of delayed shipments, status updates per shipment, cost per shipment, percentage of shipments with issues (damaged, lost, etc.), real-time location tracking per shipment, delivery confirmation times |

Material Planning for Inventory Management Dashboard

A material planning dashboard makes inventory management easier by predicting material needs and tracking their usage. It helps guarantee that purchases align with production requirements, saving time and money by maintaining the right amount of inventory. In addition, it helps prevent overstocking or running out of materials.

Who’s it for | Production planners, inventory control managers, material managers, supply chain operation managers, purchasing officers |

How often it's needed | Daily, weekly, bi-weekly, monthly, quarterly |

Covered KPIs | Material usage rate per product, projected versus actual material usage, material lead times, supplier performance metrics, inventory accuracy levels, percentage of materials meeting quality standards, work-in-process (WIP) inventory levels, safety stock levels by material, planned order releases, material obsolescence rates |

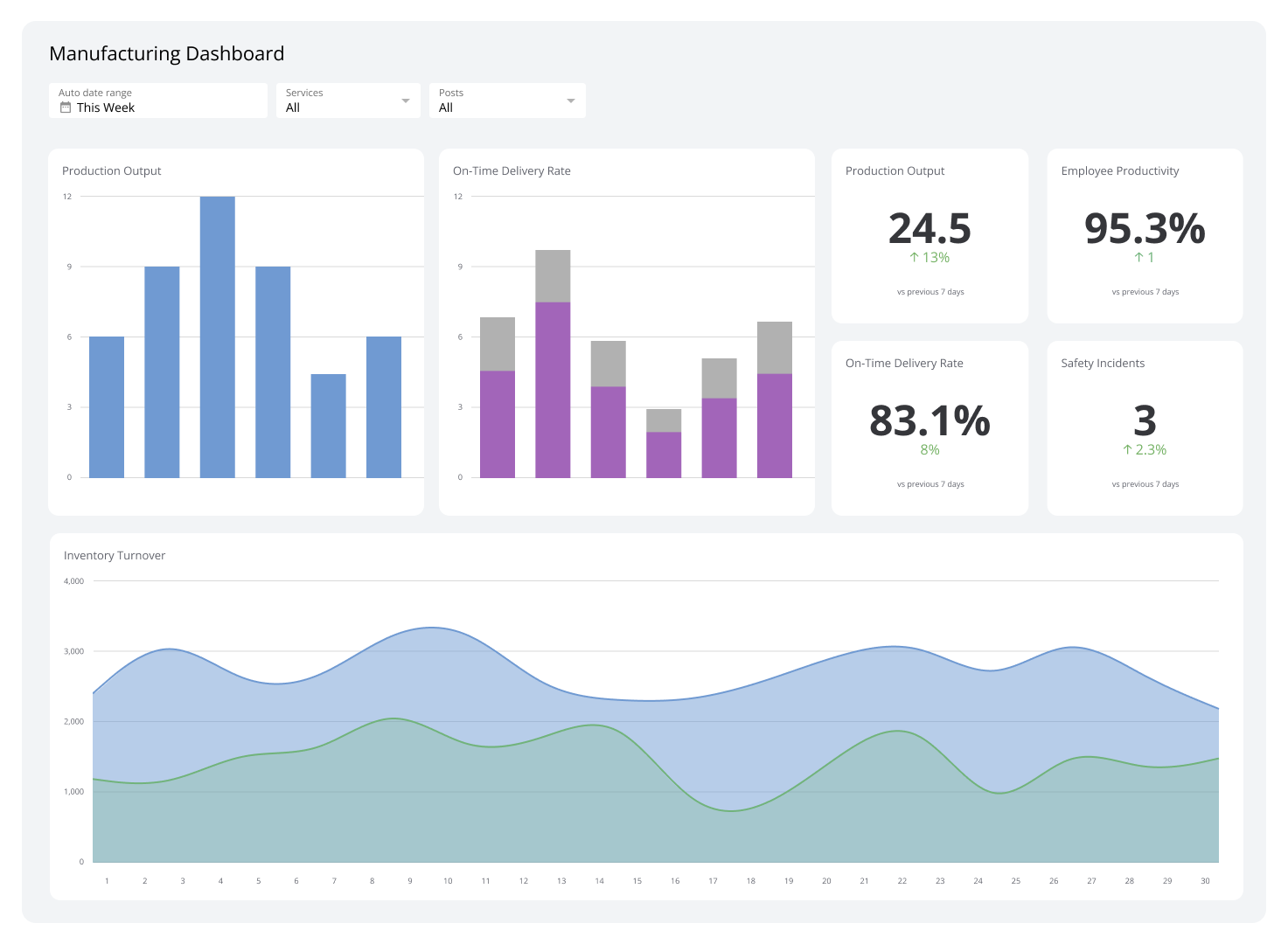

Manufacturing Analytics Dashboard

A manufacturing analytics dashboard helps your business optimize production by focusing on performance indicators directly related to manufacturing, such as production volume and downtime. It offers real-time monitoring and historical analysis of production processes and equipment efficiency.

Who’s it for | Manufacturing managers, production supervisors, process improvement analysts, quality control coordinators, operations directors |

How often it's needed | Daily, weekly, bi-weekly, monthly, quarterly |

Covered KPIs | Overall equipment effectiveness (OEE), cycle time per unit, scrap rates, percentage of product defects, downtime incidents, production volume per time frame, labor cost per item, on-time delivery rate, machine utilization percentages, yield per raw material input |

Inventory Turnover Dashboard

An inventory turnover dashboard presents metrics that assess the efficiency of inventory management by measuring how quickly stock is sold and replenished. You can use this dashboard to better understand the balance between holding costs and sales performance.

Who’s it for | Inventory managers, financial analysts, operations directors, business owners, supply chain strategists |

How often it's needed | Monthly, quarterly, yearly |

Covered KPIs | Inventory turnover ratio, sell-through rate, GMROI, sales-to-inventory ratio, holding costs, percentage of aged inventory, demand forecasting accuracy, stock-out frequency, sell-through rate, excess stock percentage |

Inventory Planning Dashboard

An inventory planning dashboard helps planners refine their inventory management processes by showing current stock levels, reviewing past purchasing trends, and forecasting future needs. This enables you to avoid having too much or too little inventory.

Who’s it for | Inventory planners, supply chain managers, operations analysts, demand planners, procurement officers |

How often it's needed | Daily, weekly, bi-weekly, monthly, quarterly |

Covered KPIs | Safety stock levels, lead times, out-of-stock percentage, inventory accuracy rate, sell-through rate, weeks of supply on hand, demand forecasting accuracy, replenishment lead time, stock-to-budget ratios, service level targets |

Supplier Performance Dashboard

Monitor vendor quality with a supplier performance dashboard. This tool shows which suppliers meet expectations, helping you streamline procurement processes and reduce costs. It also facilitates objective supplier comparisons, enabling fair contract negotiations.

Who’s it for | Procurement managers, supply chain managers, operations managers, quality control managers |

How often it's needed | Weekly, monthly, quarterly |

Covered KPIs | On-time delivery rate, quality rejection rate, cost savings, lead time, responsiveness, contract compliance, innovation contribution, sustainability compliance |

Track critical inventory metrics using Klipfolio

Inventory dashboards highlight stock levels and turnover rates, helping you spot opportunities for improvement. They support inventory managers in quickly adjusting stock and aligning strategies with overarching business goals.

Klipfolio provides essential data through a simple graphical interface, supporting informed inventory management decisions. Try it today!

Related Dashboards

View all dashboards