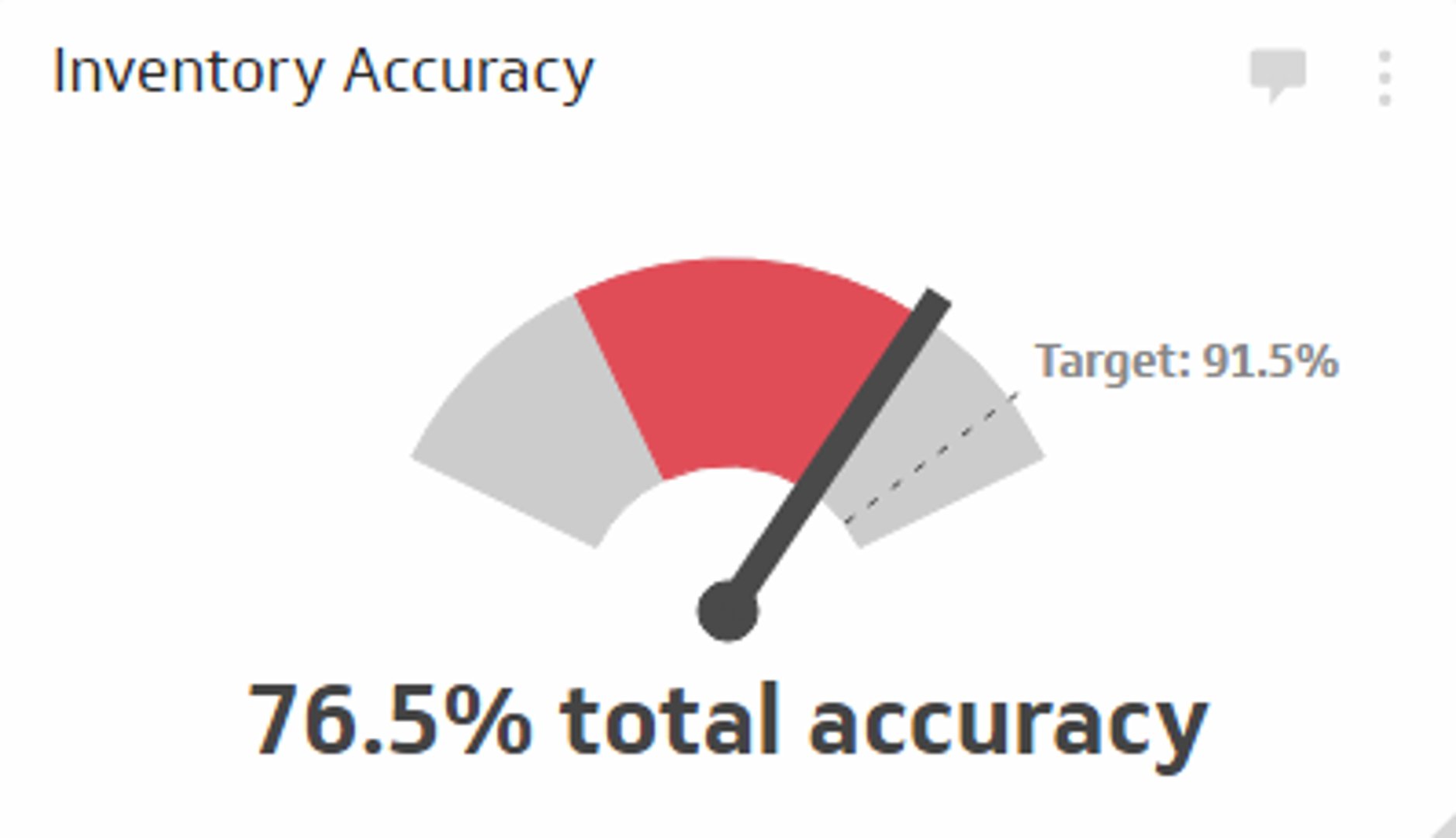

Inventory Accuracy

Measures the accuracy of your inventory by taking a headcount of items in stock and comparing it to what's recorded in your database.

Track all your Supply Chain KPIs in one place

Sign up for free and start making decisions for your business with confidence.

What is Inventory Accuracy?

The Inventory Accuracy KPI compares the accuracy of your inventory by taking a headcount of items in stock and comparing it to what's recorded in your database. This KPI requires you to perform a headcount of inventory to ensure that your bookkeeping and data management practices are in order. Inaccurate inventory tracking can result in higher costs, poor order accuracy rates, and decreased customer satisfaction.

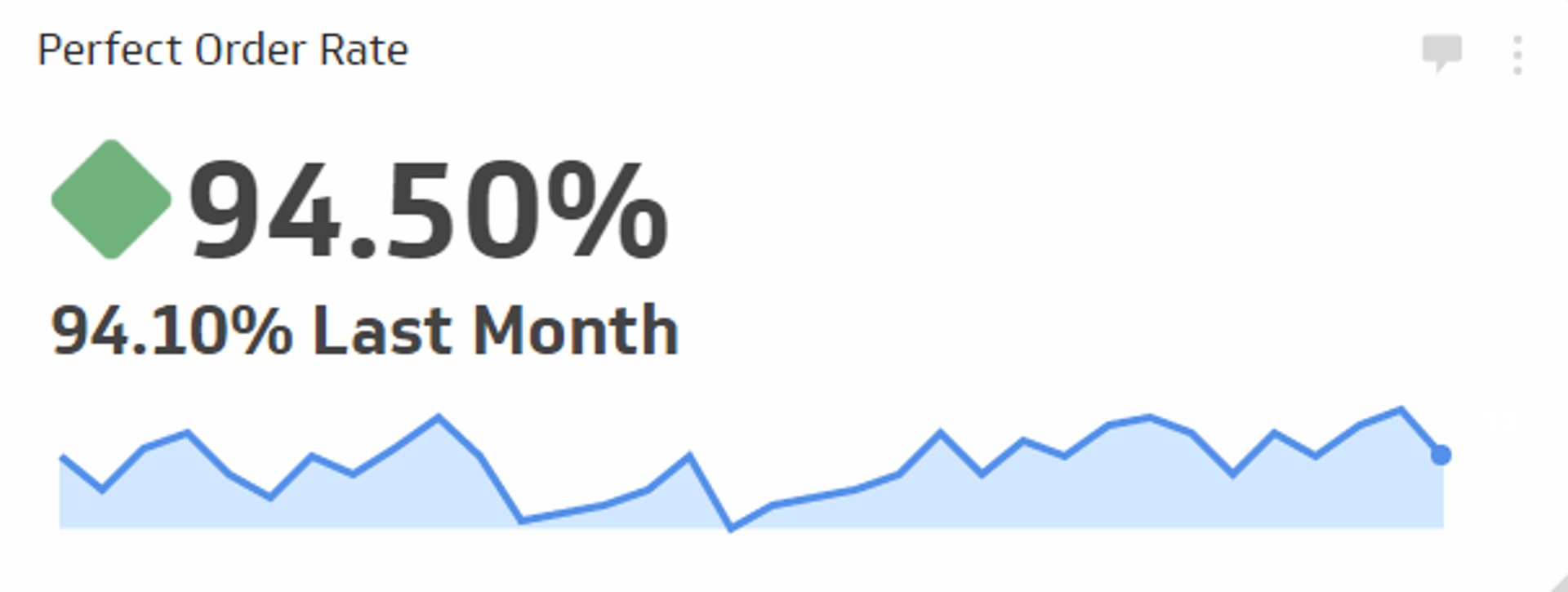

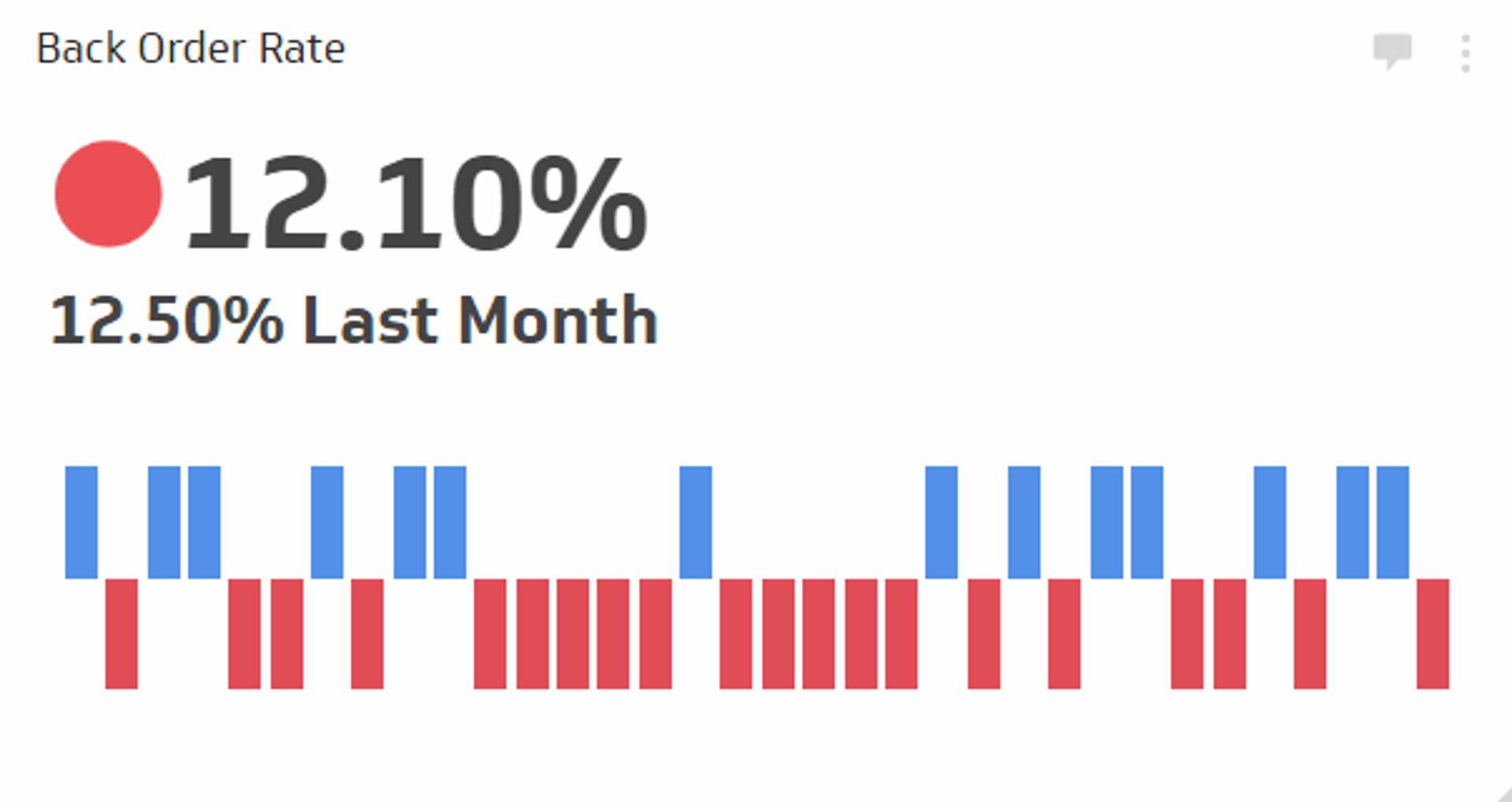

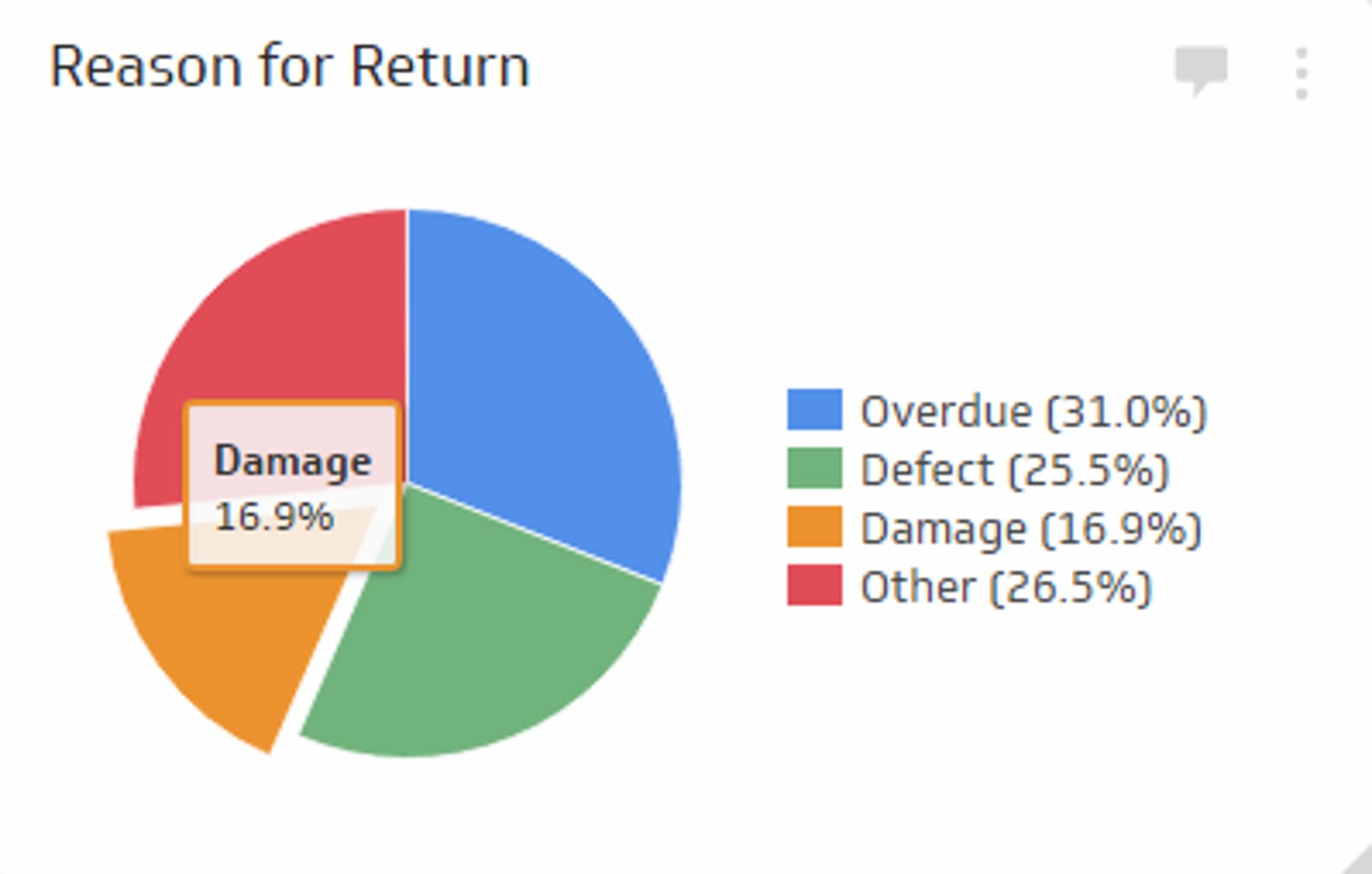

Monitoring Supply Chain KPIs on a Dashboard

Once you have established benchmarks and targets for Inventory Accuracy, you’ll want to establish processes for monitoring this and other supply chain KPIs. Supply chain dashboards can be critical in this regard.

Best Practices for Achieving Inventory Accuracy

Implementing inventory accuracy best practices can optimize your supply chain, minimize stock discrepancies, and drive overall business efficiency. Here are some practices that we find to be essential:

Implement a robust inventory management system:

- Using a reliable inventory management system is essential for maintaining accurate inventory records

- Choose a system that allows for real-time tracking of key supply chain metrics, reporting, and analysis to monitor inventory levels effectively

Conduct regular inventory audits:

- We've noticed that performing routine inventory audits helps identify discrepancies between physical inventory and recorded data

- Use methods like cycle counting, spot checks, or full physical counts to ensure inventory accuracy

Establish clear processes for inventory handling:

- Having well-defined inventory handling procedures reduces the risk of human error and data entry mistakes

- Train your staff to follow these processes consistently and provide ongoing support to maintain accuracy

Maintain organized storage and warehouse layout:

- An organized warehouse layout and storage system facilitate efficient inventory management and reduce the likelihood of errors

- Implement a logical organization system, such as FIFO (First In, First Out) or LIFO (Last In, First Out), based on your business needs

Monitor and analyze inventory data:

- Consistently analyzing your inventory data is crucial for identifying trends, preventing stockouts, and optimizing inventory levels

- Use reporting and analytics tools to gain insights into your inventory performance and make informed decisions

Invest in inventory automation and technology:

- Based on our insights, using automation and technology solutions, such as barcode scanners and RFID tags, can significantly improve inventory accuracy and reduce manual errors

- Evaluate and invest in technologies that align with your business requirements and help streamline your inventory management processes

Related Metrics & KPIs