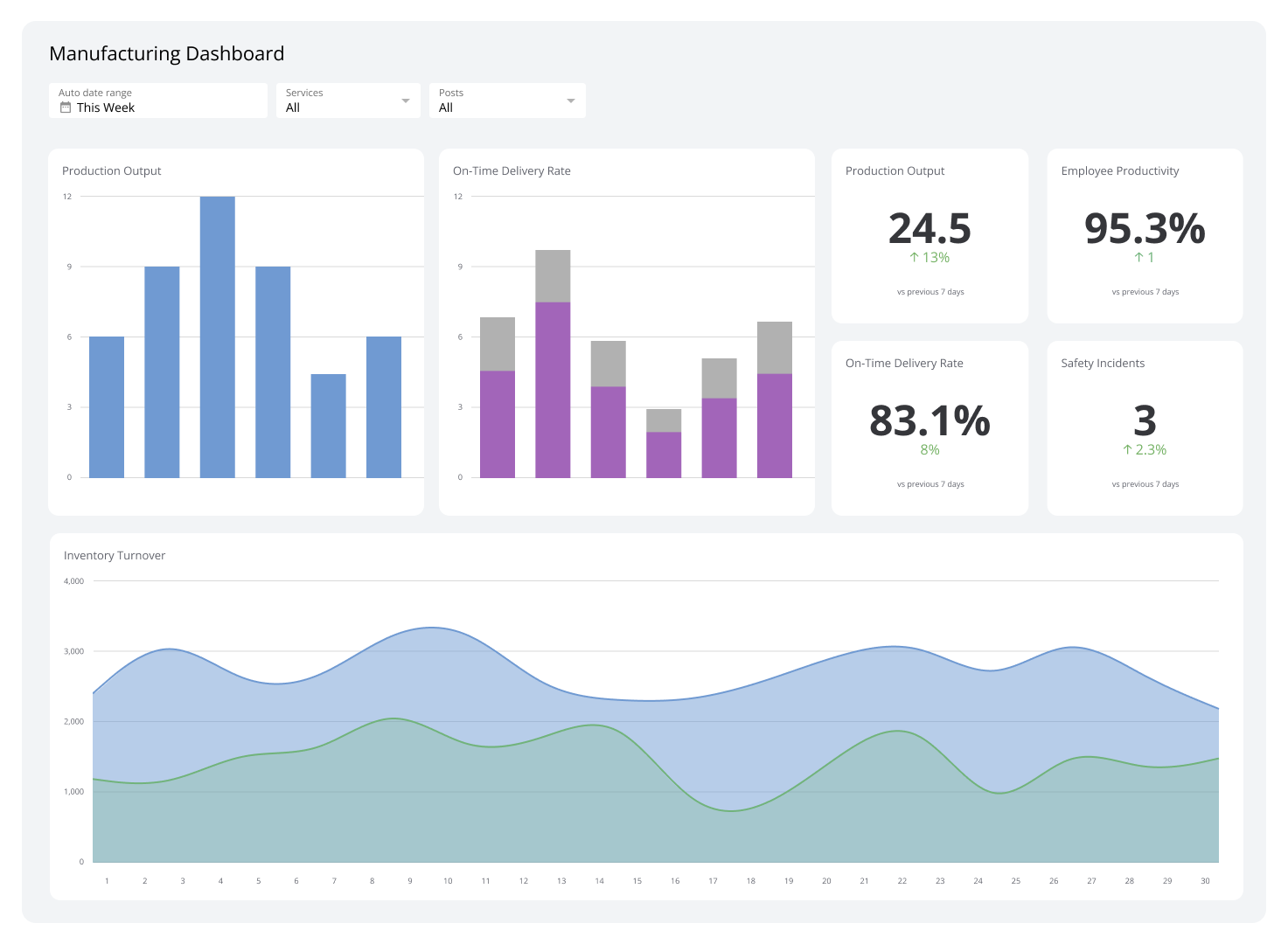

Manufacturing Dashboard

Manufacturing dashboards deliver a top-down view of all manufacturing processes in your production facilities using live data that’s simplified via straightforward and intuitive visualizations.

Track all your Manufacturing KPIs in one place

Sign up for free and start making decisions for your business with confidence.

What is a Manufacturing Dashboard?

A manufacturing dashboard lets you oversee manufacturing, with metrics and KPIs displayed using graphs, charts, tables, and other intuitive visualizations.

This dashboard often updates in real-time, gathering information from various sources, such as databases, websites, published reports, and artificial intelligence (AI). By regularly assessing your manufacturing dashboard, you can quickly identify and address production issues such as equipment failures.

More importantly, since a manufacturing dashboard provides a better understanding of the many procedures required for complete inventory fulfillment, you can have better control over your inventory.

For instance, typical manufacturing dashboards display live production rates and how they are tied to inventory levels. With this information, you can effectively alter production schedules to fulfill consumer demand without overstocking or misallocating crucial resources and revenue.

Examples of Manufacturing Dashboards

Operational Overview Dashboard

Operational overview dashboards give you a full picture of your manufacturing operations. They deliver figures on metrics like production output, inventory turnover, defect rates, and cycle times, making it much easier for you to evaluate the health of your production.

These dashboards can also help you measure worker performance through KPIs like employee productivity scores. As such, they’re instrumental in helping you maintain an efficient workforce that makes the most of the funds, equipment, materials, and other resources allocated to them.

Who’s it for | Department managers, team leaders, operations directors, project managers, supply chain managers, production supervisors, quality control managers, IT managers, customer service managers, logistics coordinators |

How often it's needed | Real-time, hourly, daily, weekly |

Covered KPIs | Production output, cycle time, on-time delivery rate, inventory turnover, equipment utilization, defect rate, employee productivity, perfect order rate, customer support ticket resolution time, average handling time, resource utilization, capacity utilization, throughput, lead time, downtime, safety incidents, process efficiency, service level agreement (SLA) compliance, mean time between failures (MTBF), mean time to repair (MTTR), first-pass yield, overall equipment effectiveness (OEE), work in progress (WIP) |

Overall Equipment Effectiveness (OEE) Dashboard

An overall equipment effectiveness (OEE) dashboard allows you to evaluate the efficiency of your manufacturing equipment and procedures. It displays metrics/KPIs related to performance, availability, and quality - the three building blocks of OEE. By doing so, this dashboard encourages you to uphold the highest standards of efficiency during manufacturing.

Examining this dashboard sheds light on many scenarios in the manufacturing process.

For example, it indicates when a particular production line has high availability but low performance, encouraging you to investigate for potential speed or throughput issues.

Who’s it for | Production managers, plant managers, maintenance supervisors, quality control managers, continuous improvement specialists, operations directors, manufacturing engineers, lean practitioners, equipment operators, shift supervisors |

How often it's needed | Real-time, hourly, daily, weekly, monthly |

Covered KPIs | Overall OEE percentage, availability rate, performance rate, quality rate, planned production time, run time, ideal cycle time, actual production count, good parts produced, total parts produced, MTBF, MTTR, setup time, changeover time, scrap rate, rework rate, first pass yield, equipment downtime, speed losses, minor stops, idling time, production losses, quality losses, production efficiency, capacity utilization, throughput rate, yield rate |

Daily Production Dashboard

A daily production dashboard visualizes data regarding the daily output and performance of your company’s factories. Standard metrics and KPIs it displays include daily production output, units produced per hour, and machine uptime.

In addition to these, it also displays labor efficiency metrics like labor hours per unit produced, letting you easily assess employee productivity.

Who’s it for | Production supervisors, shift managers, plant managers, quality control inspectors, maintenance technicians, operations managers, production planners, team leaders, floor workers, department heads |

How often it's needed | Real-time, hourly, shift-wise, daily |

Covered KPIs | Daily production output, units produced per hour, on-time delivery rate, defect rate, scrap rate, machine uptime, downtime reasons, production line efficiency, labor productivity, WIP inventory, first pass yield, cycle time, changeover time, production schedule adherence, quality control metrics, equipment effectiveness, material consumption, energy usage, safety incidents, production line utilization, throughput rate, takt time, batch completion time, overtime hours, production backlog, machine breakdown frequency, product yield, production cost per unit, inventory turnover, production volume variance |

Room/Asset Availability Dashboard

A room/asset availability dashboard supplies live insights about the occupancy and availability status of various spaces and resources within your company. With its aid, scheduling, booking, and general time management all become very straightforward.

This dashboard typically presents a live view of color-coded elements showing the layouts of rooms, equipment, or other assets. Therefore, it makes knowing whether each is available, in use, or reserved easy.

Who’s it for | Facility managers, operations managers, office administrators, IT managers, event coordinators, department heads, space planners, resource schedulers, maintenance staff, employees seeking to book rooms or assets |

How often it's needed | Real-time, hourly, daily, weekly |

Covered KPIs | Room occupancy rate, asset utilization rate, booking frequency, average booking duration, peak usage times, room turnover rate, asset downtime, maintenance schedule adherence, booking lead time, no-show rate, double-booking incidents, most requested rooms/assets, least used rooms/assets, capacity vs. actual usage, energy consumption per room, cleaning/setup time between bookings, user satisfaction rating, equipment malfunction frequency, cost per use, revenue generated (for rentable spaces), advance booking percentage, last-minute cancellation rate, resource conflicts resolved, average request processing time, asset lifecycle stage, space utilization by department, booking system uptime, accessibility compliance rate |

Inventory Management Dashboard

Inventory management dashboards give you a hands-on look at stock levels, storage capacity, and product movements. They usually prominently display metrics like inventory counts, stock turnover rates, and reorder points for individual products and entire product categories/ranges.

These dashboards aid you in better understanding their warehouses by highlighting high and low-stock-density areas.

Moreover, they feature alerts for low stock levels, upcoming expiration dates, or slow-moving items that need attention. This makes them instrumental in detecting issues like overstocking, understocking, inefficient space utilization, and stock-outs before they become critical problems.

Who’s it for | Inventory managers, supply chain managers, procurement officers, warehouse managers, operations executives, finance managers, production planners, logistics coordinators, retail managers, e-commerce managers |

How often it's needed | Real-time, daily, weekly, monthly |

Covered KPIs | Inventory turnover ratio, days sales of inventory (DSI), stock-out rate, carrying cost of inventory, inventory accuracy, order fulfillment rate, supplier lead time, reorder point, economic order quantity (EOQ), inventory shrinkage, slow-moving inventory percentage, dead stock value, inventory to sales ratio, perfect order rate, average days to sell inventory, inventory write-offs, safety stock levels, cycle count accuracy, on-time delivery rate, backorder rate, inventory aging, gross margin return on investment (GMROI), inventory velocity, stockout costs, inventory forecast accuracy, supplier performance score, average inventory, inventory holding cost as a percentage of sales, inventory-to-assets ratio, inventory obsolescence rate |

Operator Performance Dashboard

Operator performance dashboards simplify monitoring individual and team productivity within your manufacturing operations. They showcase the figures behind metrics such as picking speed, average handling times, units processed per hour, and order fulfillment times.

With the help of these dashboards, you can quickly identify the achievers of your workforce. Similarly, you’ll also get to pinpoint areas needing improvement, like bottlenecks in specific processes, operators struggling with accuracy, or teams falling behind on productivity targets.

Who’s it for | Operations managers, shift supervisors, production managers, quality control managers, human resources managers, plant managers, team leaders, performance improvement specialists, training coordinators, workforce planners |

How often it's needed | Real-time, daily, weekly, monthly |

Covered KPIs | Productivity rate, efficiency ratio, quality score, goal completion rate, error rate, downtime percentage, units produced per hour, average handling time, first-pass yield, equipment utilization rate, safety incident rate, absenteeism rate, overtime hours, compliance score, customer satisfaction rating (for customer-facing roles), cycle time, standard hours earned, rework rate, cost per unit produced, skills competency level, training completion rate, adherence to schedule, average response time, number of units processed, defect rate, machine setup time, changeover time, OEE, throughput rate, scrap rate, average time between failures, MTTR, labor cost per unit, energy efficiency ratio, material waste percentage |

Quality Control Dashboard

A quality control dashboard gives you a deeper look into the quality of the products your factory is producing. It shows metrics that emphasize essential issues, including defect rates per batch, number of customer returns, pass/fail rates for inspections, and time between quality incidents.

By doing this, the dashboard helps you identify quality problems such as defects or misscheduling. For example, you might see a sudden hike in defects from a particular production line, and you can investigate the cause, which might be anything from machine malfunctions to operator errors or raw material issues.

Who’s it for | Quality control managers, production managers, operations directors, plant managers, process engineers, continuous improvement specialists, compliance officers, supply chain managers, R&D teams, customer service managers |

How often it's needed | Real-time, hourly, daily, weekly, monthly |

Covered KPIs | Defect rate, first pass yield, scrap rate, customer complaints, product returns, on-time delivery rate, process capability index (Cpk), OEE, MTBF, MTTR, cost of poor quality (COPQ), supplier quality rating, inspection pass rate, rework rate, compliance rate, customer satisfaction score, six sigma level, total quality costs, number of non-conformances, audit findings, corrective action efficiency, training completion rate, calibration compliance, shelf life adherence, batch release time, yield by process step, packaging quality score, raw material quality rating, in-process quality checks pass rate, final product testing results, traceability compliance, environmental quality metrics, safety incident rate related to quality issues |

Supply Chain Dashboard

Supply chain dashboards offer a complete view of your supply chain operations. Using metrics like delivery rates and inventory levels, they let you evaluate your supply chain’s efficiency. On top of that, they also measure supplier performance through quality ratings, letting you determine consistently late suppliers and address them to improve your supply chain’s overall speed.

Who’s it for | Supply chain managers, logistics directors, procurement officers, operations managers, inventory managers, distribution center managers, transportation managers, production planners, chief operating officers, supply chain analysts, warehouse managers |

How often it's needed | Real-time, daily, weekly, monthly, quarterly |

Covered KPIs | On-time delivery rate, order fulfillment rate, inventory turnover ratio, days of supply, perfect order rate, supplier performance score, lead time, cost per order, inventory accuracy, forecast accuracy, cash-to-cash cycle time, return rate, backorder rate, fill rate, average days payable outstanding (DPO), transportation costs as a percentage of sales, warehouse utilization rate, inventory carrying costs, order cycle time, supply chain costs as a percentage of sales, production downtime due to stock-outs, procurement cycle time, supplier defect rate, total supply chain management costs, inventory to sales ratio, distribution costs per unit, on-time shipping rate, demand forecast accuracy, supply chain visibility index, asset utilization rate, average time to resolve supply chain disruptions, procurement ROI, supply chain sustainability metrics |

Safety and Compliance Dashboard

A safety and compliance dashboard gives you an all-around view of your manufacturing’s adherence to safety regulations and industry standards. By displaying metrics like metrics like incident rates, near-miss reports, and compliance scores, this dashboard lets you track the effectiveness of your safety protocols.

Moreover, the it helps you monitor your employee training completion and manufacturing equipment inspection status.

Who’s it for | Safety managers, compliance officers, risk management professionals, operations managers, human resources directors, facility managers, quality assurance managers, environmental health and safety (EHS) specialists, chief operating officers, legal counsel, board members, senior executives |

How often it's needed | Real-time, daily, weekly, monthly, quarterly |

Covered KPIs | Total recordable incident rate (TRIR), lost time injury frequency rate (LTIFR), near-miss frequency rate, safety training completion rate, safety audit scores, personal protective equipment (PPE) compliance rate, days since last incident, average time to close safety issues, ergonomic assessment scores, workplace hygiene compliance rate, safety observation frequency, hazard identification rate, emergency response drill performance, safety meeting attendance rate, vehicle incident rate, environmental incident rate, compliance violation rate, safety inspection completion rate, safety suggestion implementation rate, risk assessment completion rate, safety-related downtime, workers' compensation costs, safety program return on investment (ROI), safety perception survey results, regulatory fine amounts, safety corrective action closure rate, safety committee effectiveness score, contractor safety compliance rate, safety equipment maintenance compliance, incident investigation closure rate, safety communication effectiveness score |

Energy Consumption Dashboard

Energy consumption dashboards give you a snapshot of how much energy your manufacturing facilities are utilizing and gauge how efficient they are. They enable you to spot energy-hungry equipment, track the outcomes of energy-saving initiatives, and compare performance across different facilities or time periods.

Using these dashboards, you can rapidly detect anomalies in energy use, allowing for prompt investigation and correction. You can also reap benefits such as cost savings through reduced energy bills, improved sustainability, and better energy management strategies.

Who’s it for | Facility managers, energy managers, sustainability officers, chief financial officers, operations managers, building engineers, environmental compliance managers, utility coordinators, property managers, corporate social responsibility (CSR) directors, plant managers, energy consultants, green building specialists |

How often it's needed | Real-time, hourly, daily, weekly, monthly, quarterly |

Covered KPIs | Total energy consumption (kWh), energy cost per square foot, energy use intensity (EUI), peak demand (kW), energy consumption by source (electricity, gas, renewables), carbon emissions (CO2e), energy savings achieved, renewable energy percentage, energy efficiency ratio, HVAC system efficiency, lighting energy use, equipment energy consumption, energy cost as percentage of operating expenses, building energy performance index, energy consumption per unit of production, demand response performance, energy anomalies detected, energy benchmark comparisons, energy-related maintenance costs, energy storage system performance, power factor, load factor, energy waste percentage, energy conservation measure (ECM) implementation rate, energy audit findings closure rate, energy-related employee behavior scores, energy data quality index, energy forecasting accuracy, energy policy compliance rate, energy-related return on investment (ROI), energy management system uptime, energy-related regulatory compliance score |

Production Monitoring Dashboard

Production monitoring dashboards focus on real-time information regarding the output of your manufacturing operations. With their help, it becomes possible to quickly spot issues problems like unexpected downtimes or quality issues.

In addition, it also becomes easier to oversee your company's order status and inventory levels.

Who’s it for | Production managers, operations directors, plant managers, quality control managers, supply chain managers, lean manufacturing specialists, industrial engineers, maintenance supervisors, shift supervisors, production planners, inventory managers, CEO/COO (for high-level overview) |

How often it's needed | Real-time, hourly, daily, weekly, monthly |

Covered KPIs | OEE, production output, cycle time, throughput, downtime, scrap rate, first pass yield, production efficiency, capacity utilization, WIP, on-time delivery rate, inventory turnover, MTBF, MTTR, quality rejection rate, labor productivity, machine availability, setup time, order fulfillment rate, production cost per unit, energy consumption per unit, material waste percentage, production plan attainment, changeover time, production line balance efficiency, defects per million opportunities (DPMO), production lead time, production volume variance, machine utilization rate, overtime hours, production schedule adherence, safety incidents, production bottleneck analysis, yield by process step, production rework rate, production backlog, production forecast accuracy |

Streamline manufacturing operations with maximum efficiency

Manufacturing dashboards simplify the process of overseeing manufacturing operations. They showcase important metrics and KPIs, alerting you of issues. Beyond that, these dashboards help you streamline the efficiency of your employees, equipment, and production facilities.

Klipfolio’s customizable dashboards keep you informed of company production. Try it for free today!